Barcode Label Printing has Lot Many Applications starting from Retail to Industrial Labelling.

Basically We divide Labels Printing in Two Types.

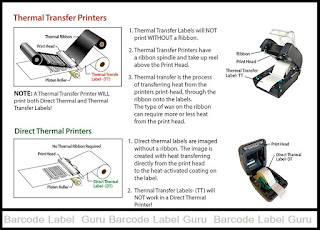

A. Direct Thermal Label Printing

B. Thermal Transfer Label Printing

ELet's Check What & When to Use in Detail

:: Watch Video Here ::

A. Direct Thermal Label Printing

Direct Thermal Printing is Used when we have Temporaty Usage of Printed Labels

Ex. Labels for Packing for Delivery, Lab Report Tags, Visitor Label, Receipt Labels, Shipping Labels & Lot More...

The Print text on label doesn't Stay for long time. Approx time to stay is for 1 Months to 6 Months depending upon paper quality used and Printing Font Darkness.

Also Direct Thermal Printed Text can be damaged by friction, Scratches and Direct or Indirect heat Etc. So the Printed Text dowsn't stay long on Labels. However If you are printing any shipping Labels or Labels for Pathology Clinical Report or Visitor Label... Such requirements doesnt Require Print Matter to stay for long, It have temporaty usage only. Thus Purpose of label printing is solved and still cost on overall project is low. and easy to ptint labels any time with low maintenance of Printer and Fast Removing & Replacing New Printing Label Roll to Print of any size require.

Direct thermal labels are a great choice when the labels ae used in controlled environments for simpler applications that have a short life span.

Direct thermal printing uses heat to selectively activate chemically treated, thermosensitive labels. The printer’s heated print-head comes in direct contact with the label, that has been coated with a material (a leuco dye) specially formulated to change color when exposed to heat. Once heated, the thermosensitive label reacts and darkens, creating the desired print.

As such, direct thermal printers use no ink, toner, or ribbon.

The disadvantage is that the image degrades over time, so direct thermal (DT) labels are primarily used for short-term use. Direct Thermal labels will fade or brown with age and will even turn black if exposed to heat or strong sunlight.

Check Below Image Explaining the Same

===

B. Thermal Transfer Label Printing

Thermal Transfer Printing is Used on Labels when we require Long Lasting Printing Details on labels with Normal Scratch Proof Durability to read details when require.

Ex. Labels on Products in Retail Shop, Labels on Packaging Boxes for Delivery, Labels on Industrial Packing Boxes, Labels on Food Packs, POS Stores & Lot More...

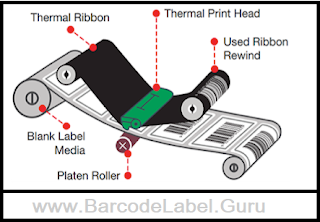

When we use Thermal Transfer Label Printing Technology, Its Requires Printers which adds Wax/Resin Based Ribbons to Support Printing Text. This will Make Label Printed Text Long Time Stay Capacity and Easy to Read or Scan the Details even after longtime whenever required. This Printing Technology will transfer heat on Labels with Transferring Wax/Resin Based Ink on Label to Print so that this type of Printer Matter will Stay for Long time on Labels.

The heated print-head is used to melt the ink coating of the ribbon, transferring it to the label. Since the label itself is not reactive, the print produced by this method is much more stable and a lot more durable. The ribbon is typically composed of either resin or wax, or a combination of the two.

Thermal-transfer labels are usually made from a thermoplastic film, but can be made of paper material as well.

Thermal-transfer printing is the most widely used printing process in the world for printing of high-quality barcodes.

Generally speaking, thermal transfer labels will last longer and be able to withstand moisture, abrasion, and exposure to UV better than direct thermal labels.

Check this Below Image to Understand the Same ::

Why we need thermal Printing Technology?

A thermal printer is inkless. They use heat to print images on the paper, which eliminates the need to spend money on ink cartridges and printing ribbons that tend to run out of ink at exactly the wrong time. By eliminating the need to replenish ink supplies, retailers save big on operational costs.

Purchase Barcode Labels on Amazon

Can you use thermal transfer labels in a direct thermal printer?

You can't use thermal transfer labels in direct thermal printers. Direct thermal printers are designed to print on specialty heat-sensitive papers. Since thermal transfer papers don't have heat-sensitive pigments, if you use them in a direct thermal printer, the printer will not produce an image on the label.

Click on Download to Download Free Barcode Label Printing Software

===

===

[posts--tag:Barcode Blog--25]